Industrial Knife Regrinding Services

Restoring performance. Extending lifespan. Enhancing productivity.

At Goldken Sdn Bhd, our core specialization lies in the precision regrinding of industrial knives. Serving a diverse range of sectors, we understand that every blade plays a critical role in your production line — and even the smallest imperfections can impact output quality and efficiency.

With advanced grinding technology, skilled technicians, and strict quality assurance, we deliver regrinding services that restore your blades to OEM-level sharpness or better, helping you achieve cleaner cuts, reduced waste, and longer tool life.

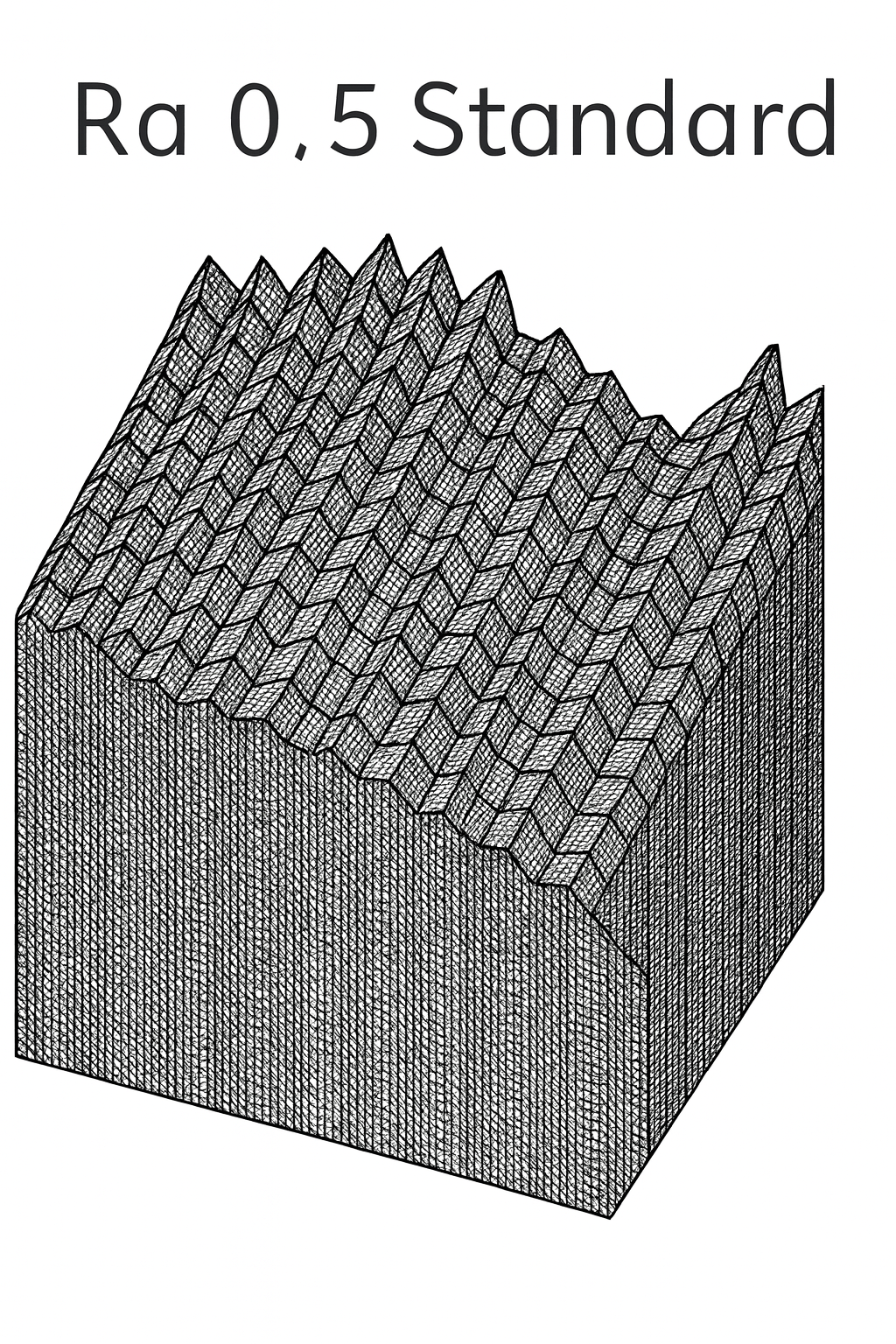

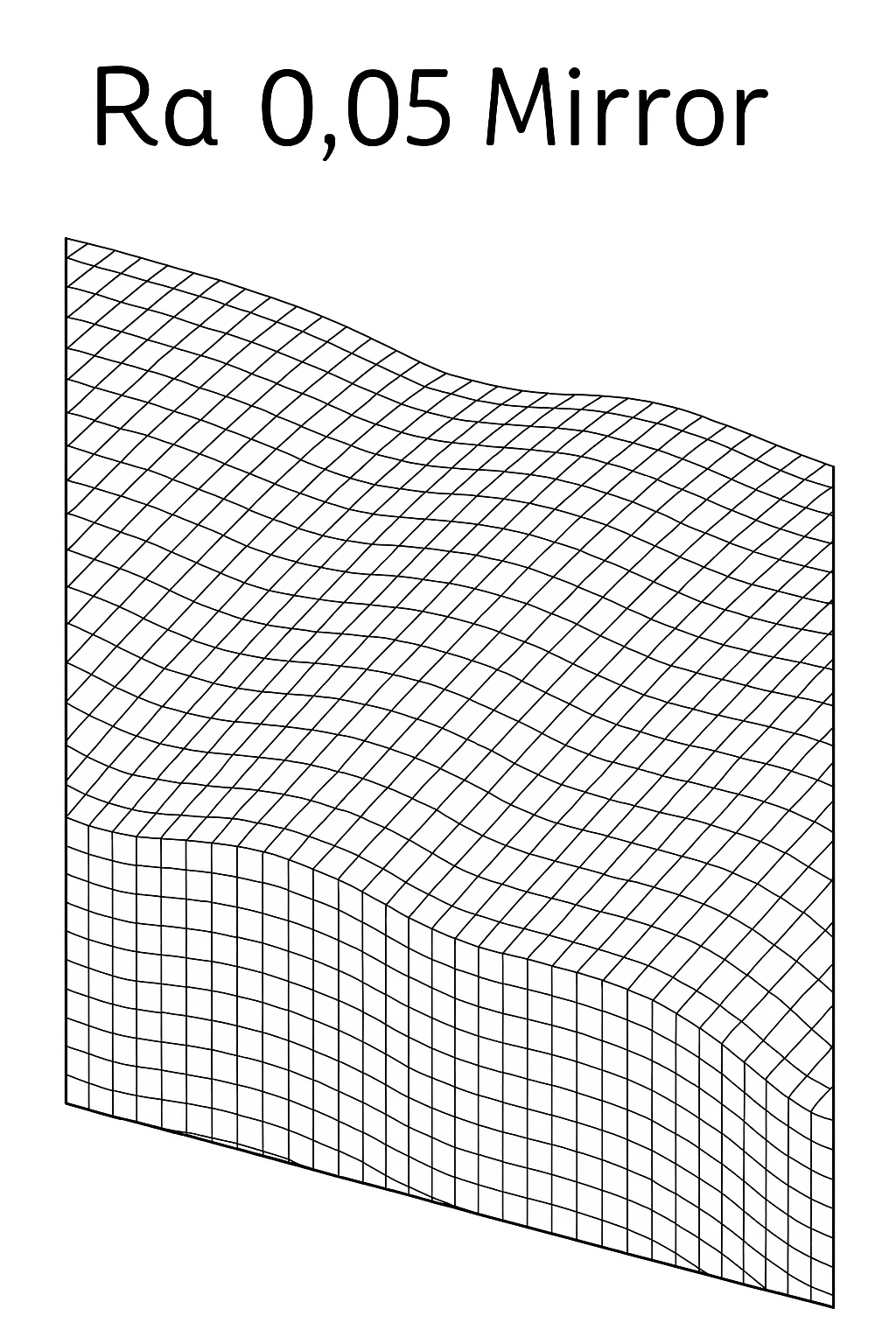

At Goldken Sdn Bhd, our grinding stations are equipped with advanced precision machinery, allowing us to offer three levels of surface finish for your industrial knives — Standard Finish, Super Finish, and Mirror Finish — based on your specific production requirements.

- Standard Finish – Ideal for general applications where consistent sharpness and durability are required.

- Super Finish – Provides a smoother cutting surface for reduced friction and improved material flow, extending blade life in high-speed operations.

- Mirror Finish – Achieves the highest level of smoothness and reflectivity, minimizing resistance and material adhesion, making it ideal for sensitive or high-precision cutting tasks.

For Tungsten Carbide Tipped (TCT) knives, we can achieve a world-class surface finish of 0.05 RA, ensuring exceptional sharpness, reduced cutting force, and optimal performance even in the most demanding industrial applications. This precision finish not only enhances cut quality but also helps maintain dimensional accuracy, extend service intervals, and lower your overall operational costs.

With our expertise and technology, Goldken ensures every knife leaving our facility meets the exacting standards of sharpness, smoothness, and durability that your industry demands.

Technical Support

Expertise that goes beyond sharpening

Application Consultation

Material selection, finish recommendations, and machine compatibility guidance.

Tool Life Optimization

Wear analysis and regrinding strategies to extend blade lifespan.

Troubleshooting

Fast diagnosis of chipping, burrs, uneven cuts, and dullness.

Production Efficiency

Optimizing machine interaction to reduce waste and downtime.

Quality Control & Reporting (Upon Request)

Precision you can see. Confidence you can measure.

Incoming Inspection

Condition checks, wear evaluation, and defect detection before grinding.

In-Process Monitoring

Angle consistency checks and calibrated grinding precision.

Final Verification

Geometry validation, sharpness measurement, and finish confirmation.

Because performance isn’t assumed — it’s verified.

Scrap Knife Collection

Responsible collection, safe handling, and sustainable disposal.

Goldken provides a professional scrap knife collection service to help you remove end-of-life blades safely and efficiently from your facility. We consolidate scrap knives, manage secure handling and transport, and ensure materials are routed to approved recycling or disposal facilities in full compliance with local environmental and safety regulations.

Our structured process minimizes risk, supports workplace safety initiatives, and contributes to your company’s ESG and sustainability goals.

Service Highlights

- Flexible Collection Scheduling: Scheduled pickups or ad-hoc collections based on your operational needs.

- Full Documentation & Tracking: Supporting audit requirements and environmental reporting.

- Safe Packaging & Transport: Preventing injury, contamination, and handling risks.

- Certified Recycling Partnerships: Maximising material recovery through approved recyclers.

Safe Disposal & Handling Support

Free Scrap Collection

Responsible collection and disposal of worn or damaged blades in full health & safety compliance.

Safety Monitoring

Regular inspection of knife guards and replacement parts upon request.

Complete Protection

From delivery to disposal, ensuring total operational safety and peace of mind.

Health & Safety Accessories

Knife Guards

Protect blade edges, extend lifespan, and enhance handling safety with durable OEM-quality guards.

Magnetic Strips

Secure, space-saving storage that provides quick access while keeping work areas safe and organized.

Protect your investment. Protect your people.

Paper & Printing Industry Blades

Supplying precision-engineered cutting tools for demanding paper, printing & converting applications. Our inventory is compatible with major systems (Polar, Wohlenberg, Horizon, etc.) and can be tailored to Malaysian industry specs.

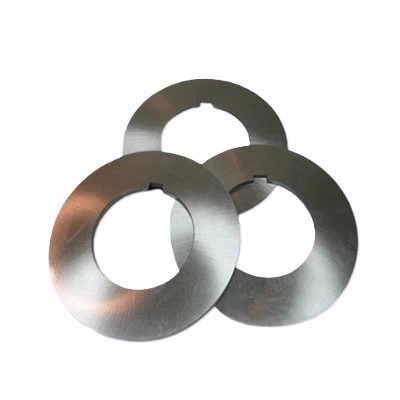

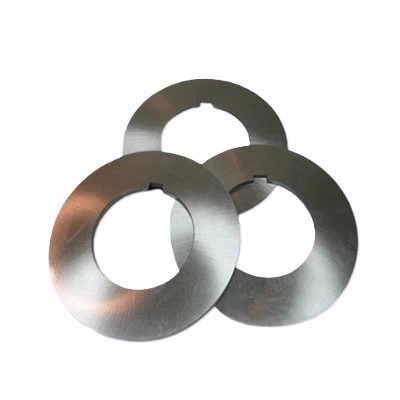

Top Slitter Knives

Precision circular blades designed for clean and accurate slitting of paper, film, and foil.

Bottom Slitter Knives

Durable circular blades designed to work with top knives for precise and consistent slitting performance.

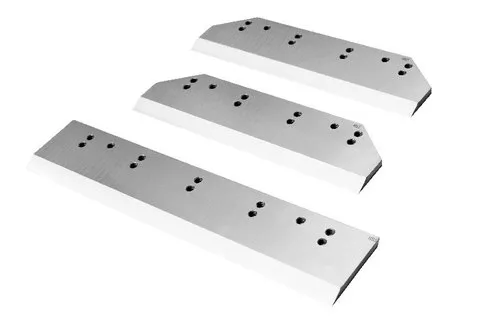

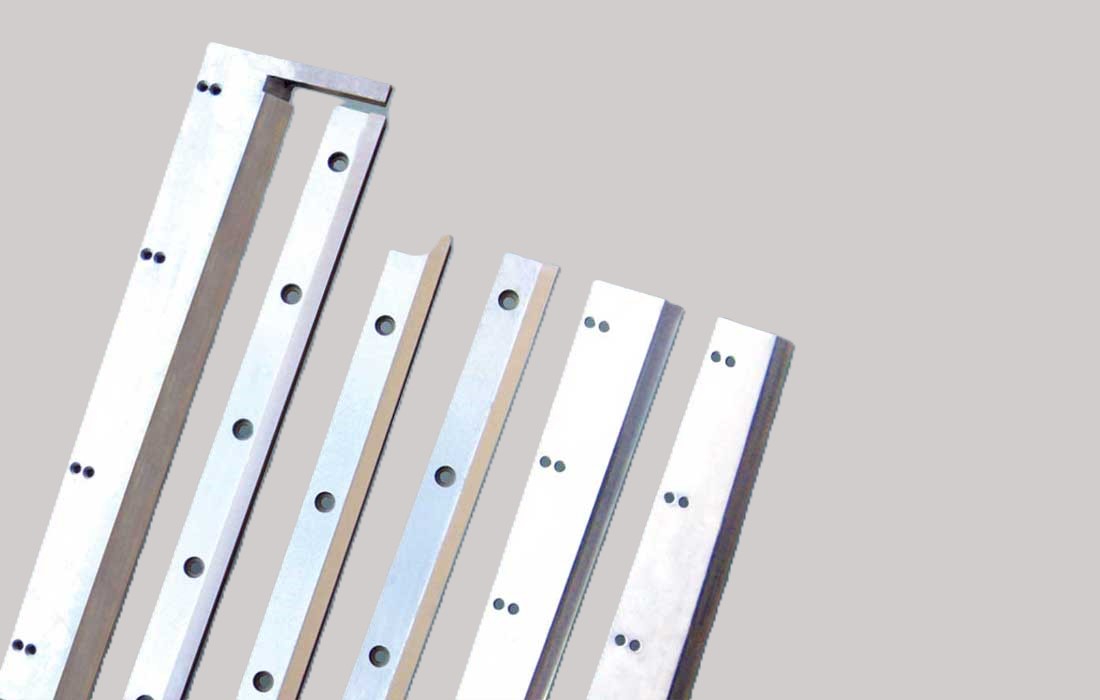

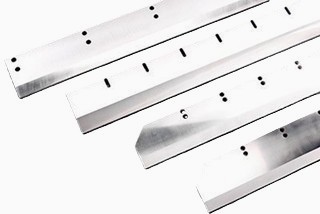

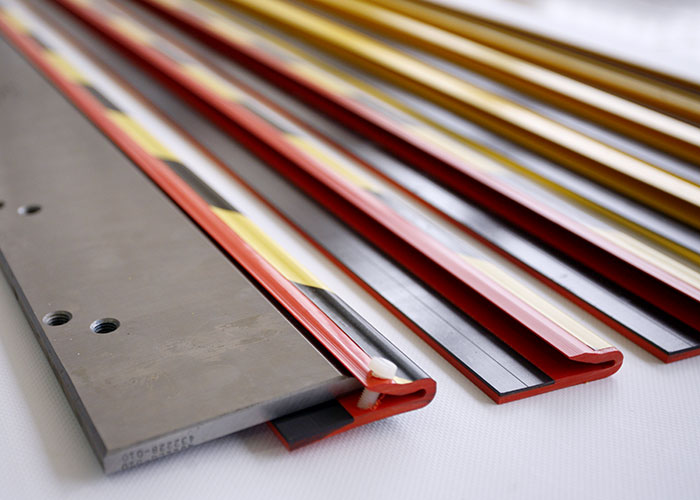

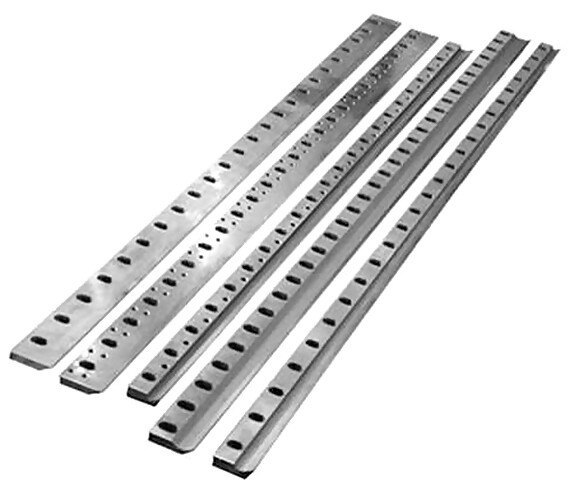

Guillotine Knives

Heavy-duty straight blades designed for powerful, precise cutting of paper, board, plastic, and industrial materials.

Three Sides Trimmer

Precision cutting knives designed for clean and accurate trimming on three sides in bookbinding and print finishing applications.

Circular Multiblock

High-performance circular tooling system designed for efficient, multi-knife slitting in demanding industrial applications.

Saddle Stitch Knives

Specialized trimming knives designed for precise edge finishing in saddle stitch bookbinding operations.

Score Cutting Knives

Precision blades designed to create controlled score lines for accurate folding and material separation.

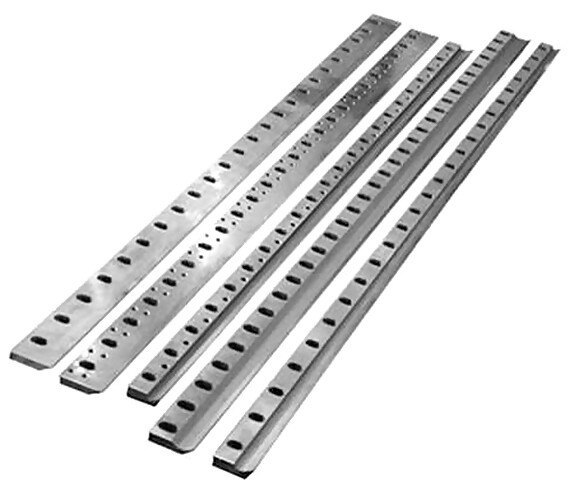

Sheeter Knives

High-precision straight blades designed for accurate cross-cutting of paper, board, and sheet materials.

Scraper / Doctor Blades

Thin, precision-engineered blades designed to control, spread, and remove excess material in printing and coating applications.

Recycling & Waste Management

Heavy-duty blades for reduction, regrind and bale handling.

Shredder Knives

Heavy-duty cutting blades designed for efficient size reduction and shredding of industrial waste and materials.

Granulator Blades

Durable precision blades designed for efficient granulating and size reduction of plastic and industrial materials.

Chopper Knives

Robust cutting blades designed for fast and consistent chopping of industrial materials in high-volume applications.

Bale Cutter Blades

Heavy-duty blades designed for safe and efficient cutting of compressed bales in recycling and material processing operations.

Rotary Palletizer Knives

Precision rotary blades designed for accurate cutting and sizing in palletizing and material handling systems.

Steel & Metal Processing

Precision slitting, shearing and coil/strip finishing.

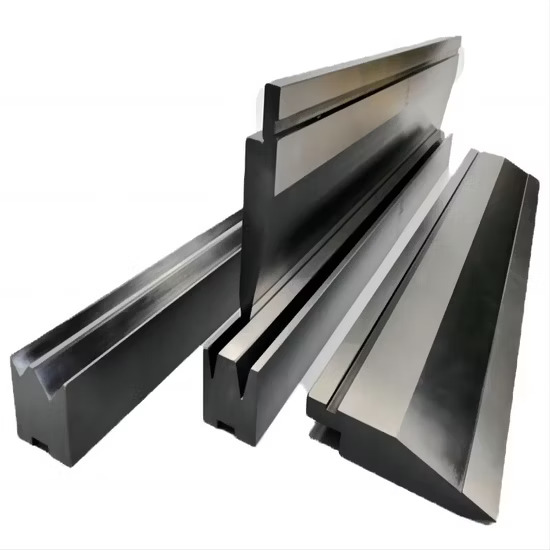

Shear Blades

High-strength industrial blades designed for precise and powerful shearing of metal and heavy-duty materials.

Slitter Blades

Precision-engineered blades designed for clean and consistent slitting across a wide range of industrial materials.

Bending Machine Blade

High-precision tooling blade designed for accurate and consistent metal bending in press brake applications.

Sheeter Knives

High-precision straight blades designed for accurate cross-cutting of paper, board, and sheet materials.

Trimmer & Cropper Knives

Precision cutting blades designed for clean trimming and cropping in printing, packaging, and converting applications.

Scrap Chopper Blades

Heavy-duty blades designed for efficient chopping and size reduction of scrap materials in industrial processes.

Wood Processing

High-uptime blades for planing, chipping and veneer.

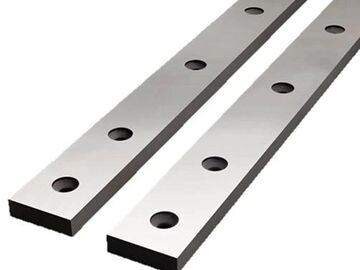

Planer Blades

Precision-ground blades designed for smooth and accurate surface planing in woodworking and industrial applications.

Jointer Blades

High-precision blades designed to create straight, smooth edges for accurate jointing in woodworking applications.

Chipper Blades

Heavy-duty cutting blades designed for efficient chipping and size reduction of wood and industrial materials.

Flaker Knives

Durable industrial knives designed for consistent flaking and size reduction in wood and biomass processing applications.

Veneer Blades

Precision-engineered blades designed for smooth and accurate slicing of veneer sheets in woodworking applications.

Saw Blades

High-performance cutting blades designed for precise and efficient sawing across wood, metal, and industrial materials.

Plastic & Rubber

Blades for granulating, slitting, cutting and converting.

Perforation Blades

Precision blades designed to create clean and consistent perforation lines for easy tearing and separation.

Foil Cutter (Zig-zag) Knives

Specialized zig-zag blades designed for clean and consistent cutting of foil and wrapping materials.

Granulator Knives

Durable precision knives designed for efficient granulation and size reduction of plastic and industrial materials.

Slitter Blades

Precision-engineered blades designed for clean and consistent slitting across a wide range of industrial materials.

Planer Blades

Precision-ground blades designed for smooth and accurate surface planing in woodworking and industrial applications.

Guillotine Knives

Heavy-duty straight blades designed for powerful, precise cutting of paper, board, plastic, and industrial materials.

Rotary Pelletizer Blades

High-precision rotary blades designed for consistent and efficient pelletizing in plastic processing applications.

Semiconductor

Precision blades for wafer and film processes.

Carbide Top Slitter

High-performance carbide blades designed for ultra-precise and long-lasting slitting in demanding industrial applications.

Carbide Bottom Slitter

Durable carbide blades designed to deliver precise, long-lasting bottom slitting performance in high-speed industrial operations.

Carbide Flat Blade

High-strength carbide flat blades designed for precision cutting and extended wear life in demanding applications.

Cutting Accessories

Safety is our priority. Goldken Sdn Bhd promotes proper handling of industrial knives and offers a free scrap blade collection and compliant disposal service to ensure worn or damaged knives are removed safely and responsibly.

To support your workplace safety initiatives, we offer a free-of-charge scrap knife collection and disposal service, ensuring that worn or damaged blades are removed responsibly and in full compliance with health and safety regulations.

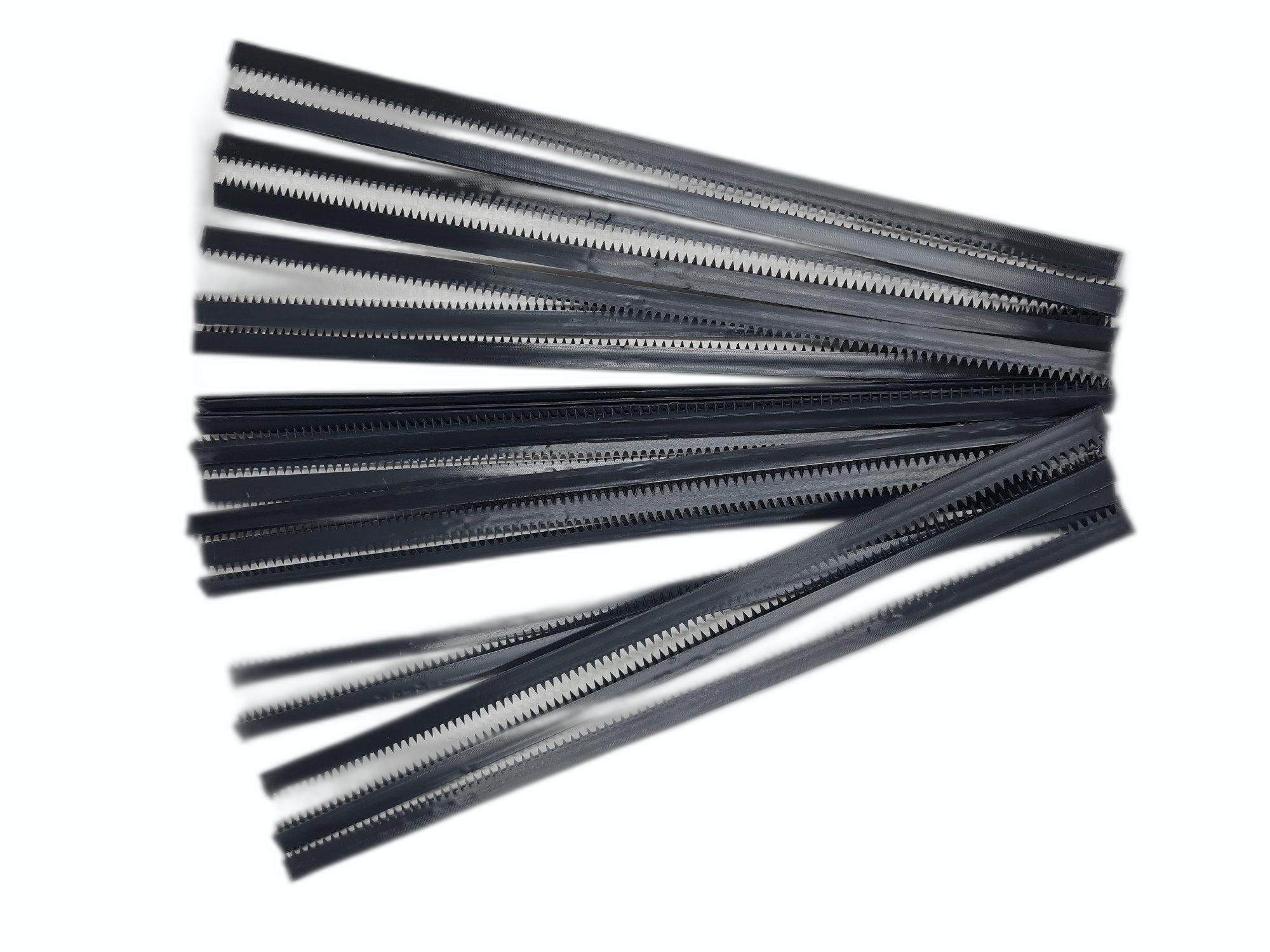

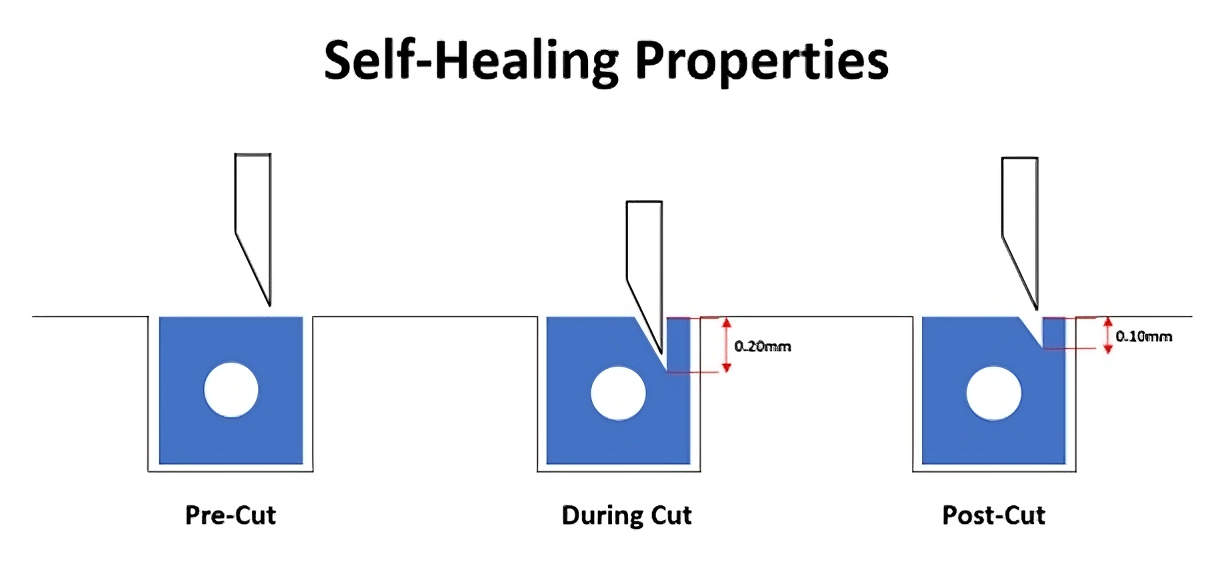

Cutting Sticks

Consistent performance and longer service life for clean cuts.

Knife Guards with End Screw

Edge protection & safe handling during transport and storage.

Magnetic Clamp Pad

Practical accessory for fixture alignment and machine setup.

Non-woven

Safety is our priority. Goldken Sdn Bhd promotes proper handling of industrial knives and offers a free scrap blade collection and compliant disposal service to ensure worn or damaged knives are removed safely and responsibly.

Top Slitter

Precision circular blade designed for clean and accurate slitting of paper, film, and foil.

Bottom Slitter

Durable circular blade designed to work with top slitters for precise and consistent cutting performance.

Sheeter Knives

High-precision straight blades designed for accurate cross-cutting of paper, board, and sheet materials.

Shear Knives

High-strength industrial knives designed for precise and powerful shearing of metal and heavy-duty materials.

Circular Multiblock

High-performance circular tooling system designed for efficient multi-knife slitting in demanding industrial applications..